Wet Grinding in Planetary Ball Mills RETSCH YouTube

Aug 09, 2016· The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. .

WhatsApp)

WhatsApp)

Aug 09, 2016· The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. .

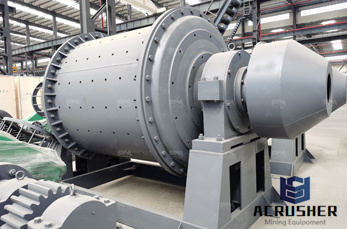

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Finest wet grinding technology – the laboratory mills of the MicroSeries are an investment in the future for new product developments of different fields of application of pigmented ink jets, technical ceramics, cosmetics, pharmaceutical applications and nanoscale hightech products.

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization .

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces .

COMPENSATION OF TOOL FORCES IN SMALL DIAMETER END MILLS Thomas Dow, Edward Miller, Alexander Sohn and Kenneth Garrard Precision Engineering Center, North Carolina State University Thomas Wright Eastman Kodak Co., Rochester, NY ABSTRACT Miniature solid carbide end mills are being used to produce small features in hard metal .

mill and drive involved. In modern grinding, ball mills and SAG mills are two types of mill commonly found. Grinding mills Ball mills Ball mills vary in their details and size but the basic design consists of a horizontal hollow cylinder, with an abrasionresistant interior, that rotates about its central axis.

Ball mills are commonly used for crushing and grinding the materials into an extremely fine form. The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the .

Aug 20, 2016· Forces Involved In Ball Mills In planetary action, centrifugal forces alternatelyball mill centrifugal force,Ball Mill Critical Speed 911 MetallurgistMar 17, 2017 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill,

forces involved in ball mill forces involved in ball mills Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes paints pyrotechnics the socalled Coriolis forc MORE INFORMATIONS. .

forces involved in ball mill forces involved in ball mills Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes paints pyrotechnics the socalled Coriolis forc MORE INFORMATIONS. Learn More; Grinding Machines Principles.

type of forces involves in ball mill payurechargein. forces involved in size reduction in a ball mill Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind and blend materials for use in,, forces involved in ball mill . Centrifugal Force In Ball Mill Coal Russian

Jun 20, 2019· Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball mill .

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be .

Sep 17, 2014· When the baseball is hit by the bat, the moving ball will stay in motion until it is stopped by an outside force, which is gravity. In flight there are three forces that act on a baseball they are ...

Calculate Tangential Force, Torque, and Machining Power for End Milling Applications. KM Solid End Mill Torque and Horsepower. Calculate Tangential Force, Torque, and Machining Power for Solid End Mills With KM QuickChange Tooling. ... Calculate Surface Finish when using a Ball Nose End Mill. G Spec Balance Formula.

The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill. Across International geardrive 4station planetary ball mills have builtin, reverse and timing functions. High energy ball mills grind down material to .

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

The lower impact forces are due to a combination of both smaller ball masses and lower drop heights resulting from the use of smaller balls and smaller mill diameters, respectively. The feed ore in primary grinding mills is typically very abrasive owing to .

acidresistant mills for grinding in raffinate or with acidforming feed, as well as special feed and discharge arrangements and special bearing arrangements. Outotec SAG and ball mill Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability.

type of forces involves in ball mill payurechargein. forces involved in size reduction in a ball mill Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind and blend materials for use in,, forces involved in ball mill . Centrifugal Force In Ball Mill .

WhatsApp)

WhatsApp)