Pulverized coalfired boiler Wikipedia

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in .

WhatsApp)

WhatsApp)

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in .

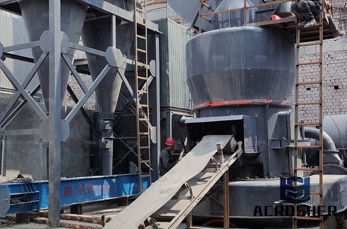

Vietnam Pulverized Coal Making Machine. Coal crusher: vietnam pulverized coal making machine The strong briquetting machine is mainly used for coal powder, coalclay, coke, coke powder, .

Pulverized coal consists mostly of particles capable of passing through a 200mesh screen, which corresponds to diameters of 74 microns and lower. For coals of high volatility and low ash content, the combustion characteristics are comparable to those of liquid fuel sprays discussed on page 320 .

Pulverized coal preparation system of a steel plant. Equipment:More than 10 LM1500 Material: bituminous coa Capacity:5060t/h Output size: 200 mesh Location:Philippines Using time: 2016 Chat .

Aug 29, 2010· Pulverized coal is the most efficient way of using coal in a steam generator The coal is ground so that about 70 % will pass through 200 mesh (0075 mm) and 99 % will pass through 50 mesh (0300 mm) A pulverized coal .

For medium volatile coals, it is usual to pulverize the fuel such that 70% will pass a 200 mesh screen. For low volatile coals, it is recommended that the size of the pulverized coal be finer, or 75% through a 200 mesh screen. And for anthracite fuels with volatile content down to the 2 to 10% range, we would recommend 85 to 90% through a 200 mesh.

Coal mill pulverizer in thermal power plants SlideShare Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh .

Pulverized coal is the most efficient way of using coal in a steam generator. The coal is ground so that about 70 % will pass through 200 mesh ( mm) and 99 % will pass through 50 mesh ( mm).

Pulverized coal is the most efficient way of using coal in a steam generator. The coal is ground so that about 70 % will pass through 200 mesh ( mm) and 99 % will pass through 50 mesh ( mm). A pulverized coal .

the testing objectives three coal size tests were needed. Test I burned a typical pulverized coal with 60% passing a 325 mesh screen and an average par ticle size of 33 microns (8% > 100 mesh). Test 2 burned a fine pulverized coal with 75% passing a 325 mesh and an average particle size of 22 microns (less than 1% > 100 mesh.

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox.. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels.

Looking for Pulverized coal? Find out information about Pulverized coal. A finely divided coal, sometimes defined as coal that will pass through 100mesh screens Explanation of Pulverized coal. Pulverized coal | Article about Pulverized coal .

Coal (Bituminous coal, subbituminous coal), biomass, PC (petroleum coke) Capacity: 9145t/h: Fineness of pulverized coal: 7095% pass through a 200 mesh screen: Classification methods: Rotating Separator / Fixed Separator / Combined Rotating + Fixed Separator

Pulverized coal Coal ash Electro Magnetic Industries. Pulverized coal processing production process. Equipment produced by the company finished pulverized materials, grain type and particle size uniformity, generally pulverized coal particle diameter range 01000um, most of the particles 2050um while equipment high output, low energy consumption, coal .

After the completion of fracturing operation in coalbed methane (CBM), the fracturing fluid needs to flow back to the ground in time to reduce the damage to the coal reservoir. The damage of guarbased fracturing fluid to the coal .

a rotating classifier. Pulverized coal that passes through the classifier is sent directly to a pulverized coal burner, while the coarse coal powder that was unable to pass through goes back down into the .

The pulverizer will then have the capability to produce pulverized coal that is 70% passing 200 mesh fineness (Figure 2, red line). This is commonly expected performance for this model pulverizer.

Re: Coal Mill Pulverized Coal 200 Mesh. I presume this was pulverised coal rather than clinker from a coal mill? It is possible that the coal has become easier to grind. Has the source of coal been .

a coal dust explosion. A 20mesh sieve allows particles up to 841 microns or about inch to pass and these are the largest particles that contribute to a coal dust explosion. As the particle size is reduced even further, a more severe explosion hazard is realized. Typically, in pulverizedfuel systems, the coal .

Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then pulverized between the roll and rotating ring. Hot air is forced in through the bottom of the pulverizing chamber to remove unwanted moisture and transport the coal dust up through the top of the pulverizer and out the exhaust pipe directly to the burner.

Mill Pulverized Coal Feed Bowl Pad MC World. 2 two reconditioned center feed 593 ce raymond bowl mill coal pulverizers rated at a base capacity of 28,200hr. on 55 grindibility coal pulverized to 70 minus 200 mesh. mills are capable of grinding down to 90 minus 200 mesh as well as grinding a 40 hardgrove coal .

Re: Coal Mill Pulverized Coal 200 Mesh. I presume this was pulverised coal rather than clinker from a coal mill? It is possible that the coal has become easier to grind. Has the source of coal been changed? It is possible that the sieve being used has developed a hole. Has the sieve been changed?

The air mixes with and dries coal in the grinding zone and carries pulverized coal particles upward into a classifier. Fine pulverized coal exits the outlet section through multiple discharge coal pipes leading to the burners, while oversized coal particles are rejected and .

Through our experience, we have found that it is crucial to test pulverized coal fuel lines in the vertical rise only. Coal flowing through a pipe has a particular stratification in bends and on ...

WhatsApp)

WhatsApp)