Kid''s Korner Apogee Interactive

Print is not supported on Firefox. Please click ''OK'' to first download this report and then you will be able to open print the downloaded pdf.

WhatsApp)

WhatsApp)

Print is not supported on Firefox. Please click ''OK'' to first download this report and then you will be able to open print the downloaded pdf.

outside the mining area for placement and storage. In the Midwest, where the surface topography and coal seams are generally flat, it is common to employ area strip mining in which the fragmented overburden is placed directly by large draglines in the space created where coal has been mined ().In some situations in the eastern United States, a coal seam occurring near the .

Dec 11, 2018· Coal mining (also called colliery) is the process of extracting coal from the ground''s surface or from deep underground. Coal miners literally raze entire mountain ranges to feed our insurmountable desire for cheap energy. There''s something brutally simple about coal mining.

Sep 11, 2017· Donkin mine, the first underground coal operation in Canada''s Cape Breton in 15 years, can process all permitted production on site as its handling, preparation and processing plant is now ...

Dec 06, 2017· Coal mining. Mining operations can negatively impact water supplies, often with longlasting effects. The fundamental issue involves contamination of nearby rivers, lakes, and aquifers by what comes out of a coal mine—usually highly acidic water containing heavy metals like arsenic, copper, and lead. The process is known as acid mine happens when certain substances (typically ...

South Australia is home to a number of massive mining operations, from significant uranium projects to the world''s largest zircon mine. The state also boasts a number of exciting new mining developments, including a project that aims to be the world''s largest graphite mine. We map out the established projects and those on the horizon.

Coal Mining. SIC 1200 | NAICS 212100. The following guide to industry information, research, and analysis provides sources for industry trends and statistics, market research and analysis, financial ratios and salary surveys, and more.

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production.

Coal mining Coal mining Coal preparation: As explained above, during the formation of coal and subsequent geologic activities, a coal seam may acquire mineral matter, veins of clay, bands of rock, and igneous intrusions. In addition, during the process of mining, a portion of the roof and floor material may be taken along with the coal seam in order to create adequate working height for ...

Coal mining and processing. DTEK Energy produces steam and coking coal, which is prepared at our plants. Total coal production for 2017 amounted to million tons. Gas coal is extracted by miners of DTEK Pavlogradugol (Dnipropetrovsk Region), DTEK Dobropolyeugol and Mine Bilozerska ALC (Donetsk Region).

Fluor''s involvement in the coal industry began in 1957 when Fluor provided construction services at the Yallourn coal mine in Victoria, Australia. Fluor would later design and construct some of the country''s major coal projects in Queensland, including Blackwater, Goonyella, Newlands, Collinsville and .

Mining is the process of mining stuff out of the ground. Any material that cannot be grown must be mined. Mining things from the ground is called extraction. Mining can include extraction of metals and minerals, like coal, diamond, gold, silver, platinum, copper, tin and iron. Mining can also include other things like oil and natural gas.

In case of allotment of blocks for PSUs, five coal mines are for power sector, nine for sale of coal and one for iron and steel. NEW DELHI: The government on Monday said it has begun the process of auction of 27 coal mines and allotment of 15 blocks to public sector undertakings. "The Ministry of ...

The Vanggatfontein Colliery is an opencast coal mining operation, owned by Wal and situated in the Witbank Coalfield of South Africa. The Colliery mines the No. 5, No. 4 and No. 2 seams using truck and shovel rollover mining methods at an average rate of 340 000tpm run of mine ("ROM").

Oct 25, 2019· This process increases the heating value of the coal. Transporting coal. Coal can be transported from mines and processing plants to consumers in several different ways: Conveyors, trams, and trucks move coal around mines, short distances from mines to consumers close to the mines, or to other modes of longdistance transportation.

Some underground mines are 1,000 feet deep. To remove coal in these underground mines, miners ride elevators down deep mine shafts where they run machines that dig out the coal. Processing the Coal. After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining site.

Coal Cleaning Process Description12,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its value. Coal cleaning processes are categorized as either physical cleaning or chemical cleaning. Physical coal cleaning processes, the mechanical separation of coal from its

Coal processing is where raw coal from the mine is cleared using different physical processes, with or without any chemical reagents, to get a product which can be sold in the market or can be used for different purposes such as power generation. Once the coal has been mined it needs to be processed.

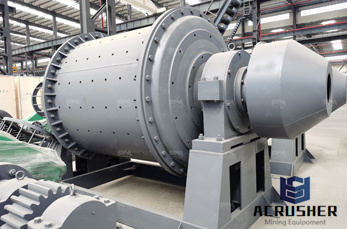

Midas Touch, How to Promote the Investment Value of Mines via Exploring, Mining and Mineral Processing? ... Magnetic separator is widely used in coal preparation and mineral processing with particle size is between 020mm, to recovery heavy particle in coal preparation plant, and remove iron ore in nonmetallic processing. Heavy media content ...

DRA is in the process of designing the coal processing plant for Resgen''s Boikarabelo mine in the Lephalale area in Limpopo province. As part of the design and verification process, DRA has to determine the plant constraints and capabilities and determine the stockpile sizes for the runofmine (ROM) and product stockpiles.

Global steel production is dependent on coal. 70% of the steel produced uses coal. Metallurgical coal – or coking coal – is a vital ingredient in the steel making process. World crude steel production was billion tonnes in 2018.

The process technology along with Grace''s CONSISTA ® catalysts enable the Datong Coal Mine Group Co., Ltd. to produce more than 200 resin grades so that .

Coal mining thrives in China. During the last week of October, more than 40,000 visitors passed through the China Coal Mining Expo, a biennial mining equipment exposition that takes place in Beijing. This year, 640 vendors...

Other underground coal mines are laid out in a checkerboard of rooms and pillars (Fig. 2), and the mining operation involves cyclical, step bystep mining sequences. The rooms are the empty areas from which coal has been mined, and the pillars are blocks of coal (generally 40 to 80 feet on a side) left to support the mine roof.

WhatsApp)

WhatsApp)