Rebar | Wire Rod Rolling Mill | World Best Biggest Rolling ...

Jan 06, 2018· c) Equipped with water quenching system (WQS) the mill is designed for TMT Bars according to all international standards. d) High hourly production (high speed .

WhatsApp)

WhatsApp)

Jan 06, 2018· c) Equipped with water quenching system (WQS) the mill is designed for TMT Bars according to all international standards. d) High hourly production (high speed .

Aug 01, 2020· To learn more about rebar, consult our guide on the different types of rebar. For more detailed information on these and other suppliers, visit the Thomas Supplier Discovery Platform, which also has a selection of more than 350 rebar suppliers including fiberglass, basalt, threaded, or stainless steel rebar, and rebar fabrication and fasteners .

16" (406 mm) bar mill roll for 3/8" rebar : 16 in 24 in cast iron : 16" (406 mm) bar mill roll for 1/2" rebar : in in nodular cast iron (18) 400 mm (") dia. uncut work rolls : in in nodular cast iron ...

mill is required. Pass Design The leader sections for the multiple slit rolling process, square, rectangular or round have to be of very close tolerance. This requires: * Correct pass profile in the rolls * Correct roll gap to ensure no overfill * Correct pass alignment between top and bottom rolls * Sound roll neck bearings and positive roll

TMT rebar mini three roll mill machine . 1. rolling mill parameter. Features: 1. Hot steel billet rolling mill. 2. Turnkey project of complete line. 3. Powerful working team and technology support. 4. Cooperated with Best China Metallurgical Design Institute. 5. Excellent user achievement and good positive feedback. 6. Very challenging project ...

Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions to match the milling solutions you need. + Product range Explore our range of roller mills. Industries. Industries Clear. Related applications. Wheat. Durum wheat.

Our mill: short stress line mill, the closed high stiffness two roll mill, threeroll opening mill, opening a tworoll mill closed tworoll mill accumulated more than a thousand units already on the market, we have also developed for rolling Hshaped steel universal mill.

Our stocking mill rolls #3 #9 ASTM A99660, A99640, and A61560 grades, including customized lengths. Rebar / Rebar Fabrication From stock length bundles to the most complex deformed/fabricated rebar, we are the region''s premier fullservice concrete steel supplier.

Nov 27, 2015· If a mill rolls 80 % of the calendar year, that is 365 x 24 x = 7008 hours. If the mill rolls 800,000 tons per year, it runs at an average production rate of tons/hour. If the utilization can be improved by 1 %, the available rolling hours is 365 x .

a three roll mill (three roll mill 101) has three horizontally positioned roller rotates in an opposite direction from the adjacent roller with a tiny gap between them, creating tremendous shear force that can finely disperse, mix, refine or .

A range of individual markings reveal the identification of each individual rebar: The first letter or symbol means producing mill and deformation pattern.. The second marking means the bar size, in this picture, " 11 " means the diameter of this rebar is #3.; The third letter represents the type of steel as follow: . S: Carbonsteel (A615).

What We Can Supply about rebar rolling mill: We can supply rebar rolling mill wire rod block mill, including designing, manufacturing, installation, and commission of the equipment with "turnkey" service. We can also design, manufacture, revamp other nonstandard equipment based on the requirements of users.

ANALYSIS OF ALTERNATIVES . ANALYSIS OF ALTERNATIVES . nonconfidential report . Legal name of applicants: Hoogovens Court Roll Surface Technologies WAVEC . Trattamento Cilindri Laminazione

Rebar Rolling Mills WireRod Rolling Mills. PREET Rebar Wire Rod Rolling Mill Capacity: 300,000 – 1,000,000 T / Year with multi strand rolling technology (Slitting Rolling Mill Technology). For Production, upto 1,000,000 T / year. PREET propose continuous rolling mill including all the latest technological features. Composed of Housing ...

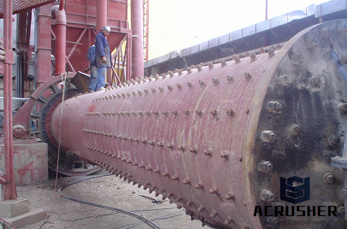

TMT rebar rolling mill production line mainly consists of the roller, rolling mill house, bearing package, bearing, workbench, rolling guide, roll adjustment device and roll changing device. Rebar rolling mill production line is for producing TMT rebar, and the main process is: after steel scrap smelting, cast into billets by continuous casting ...

Steel Rebar is available in Grade 40 which has a minimum yeild of 40,000 lbs/sqin, and Grade 60 at 60,000 lbs/sqin. Metals Depot stocks various sizes of steel rebar at wholesale prices in ready to ship precut and mill lengths or you can order online just what you need custom Cut to Size in small or large quantity.

May 31, 2012· Newfield manufactures high quality equipment for TMT / QST / Rebar Rolling Mills. Braking Pinch Rolls are used to brake the bars from a maximum speed of 25 m/sec.

3 rolls for rebar mill. 3 rolls for rebar mill Using frequent rolling cycles the Mill rolls 3 through 9 in ASTM A 99660 A 99640 and A 61560 grades often times at specific nonstandard lengths Also available are metric sizes high strength and no grade reinforcing bars Byer Steels rebar manufacturing operations is what is commonly referred to as a stocking mill

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it.. The threeroll mill has proven to be the most successful of the range of roll mills which saw extensive development .

Using frequent rolling cycles, the Mill rolls #3 through #9 in ASTM A 99660, A 99640, and A 61560 grades, often times at specific nonstandard lengths. Also available are metric sizes, high strength, and ''no grade'' reinforcing bars. Byer Steel''s rebar manufacturing operations is what is commonly referred to as a stocking mill.

The 3/8 in. x 24 in. #3 Rebar The 3/8 in. x 24 in. #3 Rebar can be used in concrete for expansion and contraction reinforcement purposes. The rebar provides ideal mechanical anchoring with the ridged design. More + Product Details Close

Epoxy coated rebar is primarily used in bridges, marine structures, parking garages and pavement and has a 30 to 50year service life. Epoxy coating patch kits are available for field repairs if surfaces are nicked or scratched. CMC Rebar operates eight epoxy coating facilities throughout the

The 3/8 in. x 10 ft. Rebar is The 3/8 in. x 10 ft. Rebar is made from ASTM A615 material for strength and durability. The rebar can be used in concrete for expansion and reinforcement purposes. More + Product Details Close

Jun 18, 2014· Roll pass design is an essential part of long product rolling process, since the long products are rolled between the shaped rolls in the long product rolling mills. Roll pass design generally means the cutting of grooves in the roll body through which steel to be rolled is made to pass sequentially to get the desired contour and size.

WhatsApp)

WhatsApp)