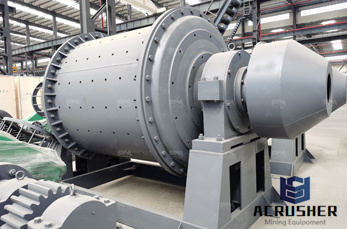

how to calculate ball millcapacity

Calculate Ball Mill Grinding CapacityThe sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empiric

WhatsApp)

WhatsApp)

Calculate Ball Mill Grinding CapacityThe sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empiric

how to calculate grinding rate of ball mill pochirajucoin. Abrasive and impactive wear of grinding balls in rotary mills saimm Apr 4, 1986, sities of the two components in the rate of ball wear In discussions of the formula given in equation (1). [Chat Online]

of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw. Morrell (1996) proposed a mathematical model for autogenous, semiautogenous and ball mills which is based on the motion of grinding charge inside the mill.

how to calculate grinding media in a ball mill in cement industry. Re: how to estimate the wear rate for Ball mill International .The ball charge mill consists of grinding media in various sizes to ensure ..

Calculation of ball filling ratio in grinding mil. There are many factors affecting the working effect of ball mill, and the grinding ball filling ratio is a major parameter of grinding of ore In the grinding process, grinding mill is mainly rely on the role of media to plete the grinding task, and whether the medium filling rate is reasonable or not is the first factor to affect productivity

Calculate and Select Ball Mill Ball Size for Optimum Grinding. In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

How To Calculate Grinding Rate Of Ball Mill. how to calculate grinding rate of ball mill kilawarhing. About. CBcrusher''s technical support team which is throughout the world and have the professional knowledge level will help you to solve the problems that you meet in the using process of the mining and construction equipments.

How To Calculate The Grinding Time Of The Ball Mill . It is assumed that the ore is continuously discharged from the feeding port to the discharge port the ball milling time calculated under this ideal state is the minimum grinding time the filling rate of the ball mill is 40 if .

Abrasive and impactive wear of grinding balls in rotary mills saimm. Apr 4, 1986 ... sities of the two components in the rate of ball wear. In discussions of the formula given in equation (1),.

Calculate Top Ball Size of Grinding Media FRED C. BOND Equation Method. 2. The second study was used to develop a correlation between ball mill operating data and grindability test data. This was based on the Work Index concept. From this concept came two equations: (a) the equation to determine the Work Index from Bond grindability tests,.

rate grinding wear. wear rate of grinding media in ball mill . Grinding Balls amp; Rods Mineral Processing amp; Metallurgy. One of the economic factors of grinding is the wear of the grinding mediaThis is dependent upon the material used in its manufacture, method of manufacture, size of media, diameter of mill, speed of mill, pulp level maintained in the mill, rate of feed, density of pulp ...

Nov 08, 2017· DETALS ABOUT CEMENT BALL MILL GRINDING MEDIA CALCULATION . Now chatting: Contact Us: Cement Mill Notebook "In Grinding Ball Charge in . Contact Us For Help: how to estimate the wear rate ...

Calculate Ball Mill Grinding CapacityThe sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empiric

It is assumed that the ore is continuously discharged from the feeding port to the discharge port. The ball milling time calculated under this ideal state is the minimum grinding time. The filling rate of the ball mill is 40%. If the slurry level reaches 50% filling rate, the slurry will flow out automatically.

Grinding Media Wear Rate Calculation in Ball Mill 911 Metallurgist. Apr 29, 2017 ... In the previous discussion the fact was established that the work done by a ball when it strikes at the end of its parabolic path is proportional to...

how to estimate the wear rate for Ball mill CemNet. · How to estimate the Grinding media wear rate for cement grinding ball mill and how much makeup load we have add to get ... how to estimate the wear rate for Ball mill.

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same. thanks. sidhant. reply

how to calculate grinding rates for ball mill[crusher mill] how to calculate ball mill filling XSM how to calculate ball mill filling is a professional manufacturer ofhow to calculate ball mill filling grinding, how to estimate the wear rate for Ball mill How to estimate the Grinding media wear Chat With Sales.

Jan 30, 2018· Telephone: Telephone: Contact Person: Fax:— Well,there is no precise calculation method that can accurately calculate the specific capacity of the cement ball are...

how to calculate grinding rates for ball mill%3f how to calculate grinding rate of ball mill calculate grinding ball diameter for ball mill. sion equation between the wearing rate of the steel balls and the grinding conditions . Key WOI''dS wearing performance steel ball ball mill . diameter D, and t be the time during which the .

How To Increase Ball Mill Grinding Rate. Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users. We also choose us as a successful enterprise and a bright future for you!Please fill ...

Calculation Of Grinding Media In Ball Mill Calculation for grinding media in ball mill kudulodgealculate grinding media sizes for ball mill bpes018 06 27 to calculate the needed grinding work against the grain size changing three semi grinding degree is the ratio of the sizes from the grain sag mills are autogenous mills but use grinding balls like a ball mill.

grinding mill would allow for more efficient operation of these grinding mills. We will look at ... that width of screen surface is the most important factor in determining the capacity ... SAG Mill (semiautogenous) followed by Secondary Ball Mill. Read More

WhatsApp)

WhatsApp)