Amino acids key to new gold leaching process

Oct 24, 2014· "In normal gold leaching you would leach with cyanide and then absorb the gold cyanide on to a carbonate leach carboninpulp. "You do something similar with glycine, it forms a gold .

WhatsApp)

WhatsApp)

Oct 24, 2014· "In normal gold leaching you would leach with cyanide and then absorb the gold cyanide on to a carbonate leach carboninpulp. "You do something similar with glycine, it forms a gold .

Leaching. There are two main leaching methods: heap leaching and insitu leaching. Heap leaching is the most common method used in the When processing copper through heap leaching, vast quantities of ore and overburden overburdenSoil and rocks that have been moved out of the way to get to ore are called "overburden." In areas where there ...

The leaching of gold from the mercury amalgamated tailings with cyanide could increase the health risks associated with mercury and cyanide exposure to miners and the surrounding –18 When mercury combines with cyanide it forms highly soluble complexes such as anionic mercury (II) cyanide ([Hg(CN)4] 2−), which is stable at a pH ...

Heap Leaching. Environmental issues with heap leaching are centered on the failure to keep process solutions within the heap leaching circuit. Release of toxic heap leaching fluids into the environment can affect the health of both the surrounding ecosystem and human population (Reichardt, 2008).

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

lurgical gold extraction routes utilize a leaching step to produce a goldbearing solution as an intermediate product while the recycling of secondary gold from electronic and precious metal scrap is based on the selective and fast dissolution of the precious metal. Therefore, A Method for Leaching or Dissolving Gold from Ores or Precious

Mining technology consists of the tools, methods, and knowledge used to locate, extract, and process mineral and metal deposits in the earth. The methods used to locate ore bodies range from ontheground reconnaissance by prospectors to remote sensing techniques such as satellite imagery.

A 3D Pot of Gold CDM Smith implemented the project''s new heap leach mining system, where excavated raw ore is crushed and reduced into fine pellets, stacked on a liner or leach pad, and then irrigated with sodium cyanide to separate the gold from solids.

Heap leach piles can cover tens to hundreds of acres ( to 1 km2) and be a few hundred feet (about 100 m) high. They resemble waste rock piles in location and size, but are more precisely engineered. Slag is a glassy byproduct of smelting; slag piles can cover tens to hundreds of acres ( to 1 km2) and be over 100 hundred feet (30 m) high. ...

California''s Legacy Abandoned Mines Physical Hazards Assessment Environmental Hazards Assessment . In 2000, the Department''s Abandoned Mine Lands Program (AMLP) published California''s Abandoned Mines: A Report on the Magnitude and Scope of the Issue in the State.

Aqueous methods divided into Placer (Panning, Sluicing, Hydraulic Mining, and Dredging) and solution methods (Insitu leaching (ISL) and Heap Leaching). Among them, solution mining and placer mining are renowned as the best methods; however, it is limited to specific types of mineral deposits ( .

• In Chile, the share of copper exports in the total export of goods rose from an average of 38% in to 61% in 2006(McMon, 2014; • Gold exports in Ghana rose threefold from 1990 to ...

methods, and precious metals, particularly gold and most notably in the USA and Australia, tend to be recovered in recent years from lowgrade deposits by surface mining. Figure 1a. Production size distribution of metal mines for the period 1988 to 1997 in the western world Figure 1b.

Background Assessment of OSH Hazards Exposure of Workers in SSGM ASSM – Informal out of the mainstream The Philippines ranks 22nd among the list of world''s gold producing countries in 2017 and 5th among the 6 Asian countries producing 91% of the precious metal in the continent About 236,000 workers are employed in mineral industry (EMBDENR, 2016)

• Heap Leaching • Heap leaching was introduced in the 1970''s as a means to drastically reduce gold recovery costs. This process has literally made many mines by taking low grade geological resources and transforming them to the proven ore category. Ore grades as low as oz Au per ton have been economically processed by heap leaching 8.

Highly toxic sodium cyanide has been found in a product that has been reported to the Department of Mines and Petroleum (DMP). The product was advertised by an overseasbased company as an "environmentally friendly" alternative for gold processing.

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process. Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore). Having a quick look now at how porphyry ores are treated and the metals extracted. There are two main ...

Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890''s, cyanide has been used to recover gold from gold bearing ores. And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal.

But as the effects of cyanide are getting more obvious, the opposition to cyanide leaching in gold mining is also increasing. The use of cyanide in mining causes an unreasonable risk to the health of people, wildlife, and fish. As the hazards of cyanide in mining process are very much obvious, it is the responsibility of the Government and ...

Leaching, often gold, is the process of extracting a soluble constituent from a solid by means of a solvent. In extractive metallurgy, of gold, it is the process of dissolving a certain mineral (or minerals) from an ore or a concentrate, or dissolving certain constituents from materials such as a calcines, mattes, scrap alloys, anodic slimes, etc., to achieve either one or two purposes ...

Due to the use of dirty practices such as open pit mining and cyanide heap leaching, mining companies generate about 20 tons of toxic waste for every gold ring. The waste, usually a gray liquid sludge, is laden with deadly cyanide and toxic heavy metals. Many gold mines dump their toxic waste directly into natural water bodies.

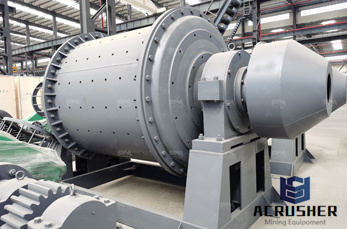

rock crusher toake gravel greenrevolutionorgin. Rock crusher A rock crusher is a machine designed to take large rocks and reduce them to smaller rocks gravel or rock dust Rock crushers produce aggregates and ready to process mining ores as well as rock fill material for landscaping and erosion control

Different ore has different gold leaching process, different ore with different properties must adopt the proper gold leaching is a brief introduction of the common gold leaching methods for gold mining plant. Extraction of gold from ore should be at least two steps, first of all, the prepared work, also called pretalking work, which can be formed by crushing and separating ...

Lead and Mercury Emissions from Mining. Global releases of lead from smelting and refining nonferrous metals ( gold, lead, zinc, copper) total over 28,000 metric tons/year. 1 Global releases of mercury from smelting and refining nonferrous metals total 710 metric tons/year – .

WhatsApp)

WhatsApp)