Rolling Machine Harry Harry Medium

The rolling machine, also known as extrusion mill and roller mill, is a new type of cement energysaving grinding equipment. It has a highefficiency, lowefficiency ball mill pregrinding system.

WhatsApp)

WhatsApp)

The rolling machine, also known as extrusion mill and roller mill, is a new type of cement energysaving grinding equipment. It has a highefficiency, lowefficiency ball mill pregrinding system.

Energy efficiency IsaMill Advantages Isamill. The high energy efficiency of stirred mills compared to ball mills is well understood. The use of tower mills as an energy efficient alternative to secondary and regrind ball milling became a common inclusion in the latter part of the previous century.

Oct 08, 2019· Remove all; Disconnect; The next video is starting

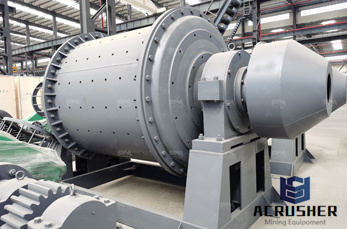

A overflow ball mill with rolling bearings, high efficiency and energy saving. Advantages • The transmission machinery of Energy saving overflow ball mill substitutes large scale double row self aligning roller bearing for sliding bearing, so it is easy to start and saves energy by 20 30% .

Henan Ascend Machinery Equipment Co., in the production of crusher, wet pan mill, ball mill, Raymond Mill, cement equipment and other products, providing ore selection, pharmaceutical experiments, process design and other professional services. The main products are jaw crusher, impact crusher, hammer crusher, raymond mill, magneticseparator and other equipment, can be tailor ...

The large scale of the IsaMill™ makes that efficiency available to mainstream grinding. The high energy efficiency of stirred mills compared to ball mills is well understood. The use of tower mills as an energy efficient alternative to secondary and regrind ball milling became a common inclusion in the latter part of the previous century.

Modern Processing Techniques to minimize cost in Cement Industry Batra, Mittal, Kamal Kumar P N Chhangani ... ease of crusher operation and improved energy efficiency. ... system claims to have advantages of ball mill, roller mill and roller press in

Cylindrical energy saving grid ball mill is one of energy saving mills developed by Xinhai, which is easy to start and saves 2030% energy. ... A high efficiency and energy saving ball mill with rolling bearing 【 Capacity 】: Up to 160t/h ... Large double row selfaligning roller bearing with low friction force is used to replace sliding ...

caculations of ball mill project efficiecy performance process performance. ... focused on the energy and cost comparisons of the existing AG/SAG ball mill ..... Table Calculation of ball mill circuit specific energy ... Chat Now; Calculation Of Performance Of Ball Mill ball mill performance calculation Quarry Crusher Machine ...

heat mass balance for vertical raw mill – Grinding Mill China. ... INDUSTRY SECTORS – CEMENT – Energy Efficiency Guide for . can be an air swept ball mill or vertical roller mill . flows with heat and mass . a material and energy balance is to be carried out for a raw mill.

1. The energy consumption rate of the ball mill is relatively low. At present, there is a tendency to be replaced by vertical mills, roller presses, etc., but the ball mill has a "granular shape that is approximately spherical, which is conducive to raw material calcination and cement hydration hardening".

Transfer Size, T80, microns Ore SG Ball Mill Grindability, kWh/ton Average No ENERGY REQUIREMENTS CALCULATION: Pebble Crusher, Y/N From SAGDesign testwork results. Notes Ball Mill Reduction Ratio, RR Inefficiency for coarser feed to ball mill Inefficiency for finer final product size Efficiency for BM diameter other than 8 ft MILL PINION ENERGY ...

Ringroller mill Ring ball mill High pressure grinding roll Roller and Ringroller mills. Overview crusher and mill types Pin mill Impact mill with screen Fluidized bed mill Impact Mills . ... Conclusions regarding energy efficiency Energy transfer factor is important to characterize the mill beside Type of stress Stress energy distribution

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Mill Series. We are a professional manufacturer of sand maker, sand washer and sand collecting system. According to the mobility, sand makers can be divided into PP Series mobile sand making plant and VSI Series standalone sand maker.

offers 3,005 efficiency ball mill products. About 56% of these are mine mill, 1% are ceramics, and 1% are other fabrication services. A wide variety of efficiency ball mill options are available to you, such as free samples, paid samples.

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills. Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation ...

Grinding in Ball Mills: Modeling and Process Control Vladimir Monov, Blagoy Sokolov, Stefan Stoenchev ... the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product. ... influence on the particle breakage rate and energy efficiency of the grinding process ...

Cylindrical energy saving grid ball mill is one of energy saving mills developed by Yantai Group, which is easy to start and saves 2030% energy. It is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding. In addition, the .

grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalent.

Limestone is an important building material, after being processed by crusher and ball mill, it can be used as the main raw material for the production of cement and lime. Ball mill is one of the high fine grinding machines widely used in industrial the processing and production of lime powder, the ball mill is an indispensable key equipment.

Request PDF on ResearchGate | Comparison of energy efficiency between ball mills and stirred mills in coarse grinding | Stirred mills are primarily used for fine and ultrafine grinding. They ...

vertical roller mills performance seekonzertech. Vertical Roller Mill repair Castolin Eutectic Vertical Roller Mill repair Our long experience with Vertical Roller Mill repairs Excellent references In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency,...

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

WhatsApp)

WhatsApp)